Hydraulics

-

Read more »

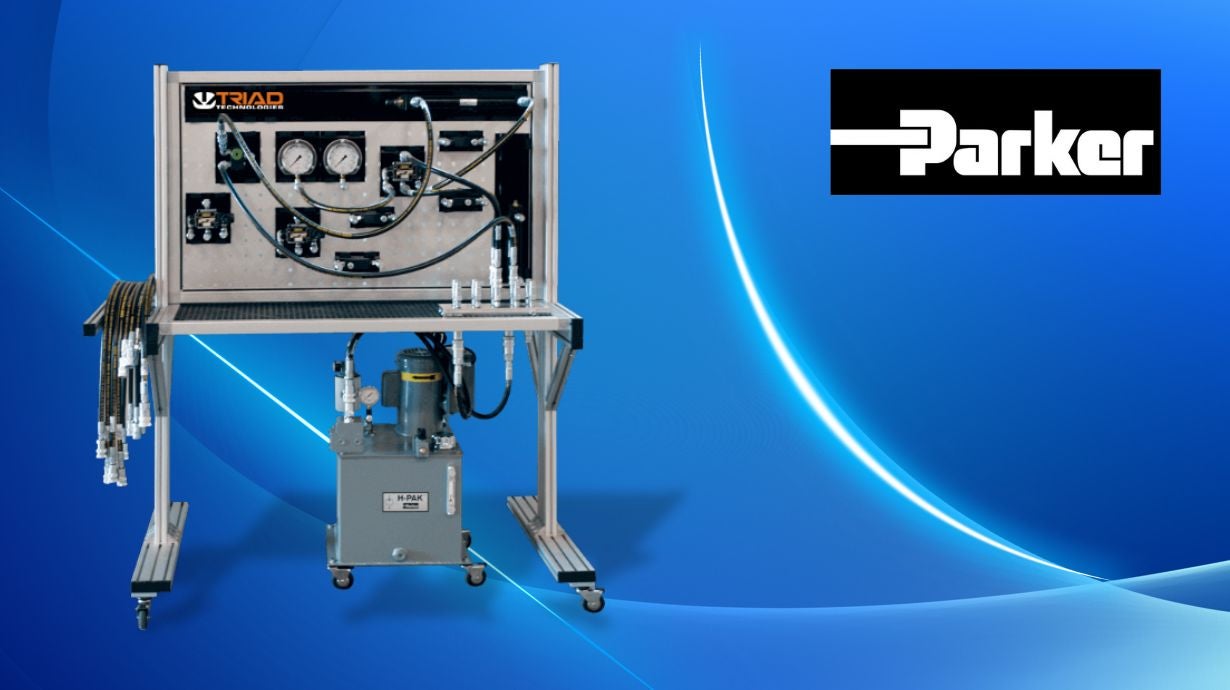

In today's rapidly evolving industrial landscape, the gap between theoretical knowledge and practical, real-world skills is widening. Whether you are aiming to upskill your existing workforce to handle advanced machinery or prepare your students for successful entry into high-demand motion and control professions, the need for hands-on, high-quality training has never been more critical. This is where specialized, industrial-grade training equipment makes all the difference. Triad Technologies offers the Parker Modular Training System, a flexible, comprehensive solution designed to bridge the skills gap in fluid power and control using the same components professionals use on the job.

Posted: December 09, 2025 -

Read more »

At Triad Technologies, we understand the demands placed on modern hydraulic systems. Space is tighter, equipment is working harder, and every minute of downtime costs you. That's why we're proud to distribute Parker's innovative GlobalCore 777 hose, a game-changer designed to tackle the most common headaches in your operations.

Posted: December 03, 2025Categories: Hydraulics -

Read more »

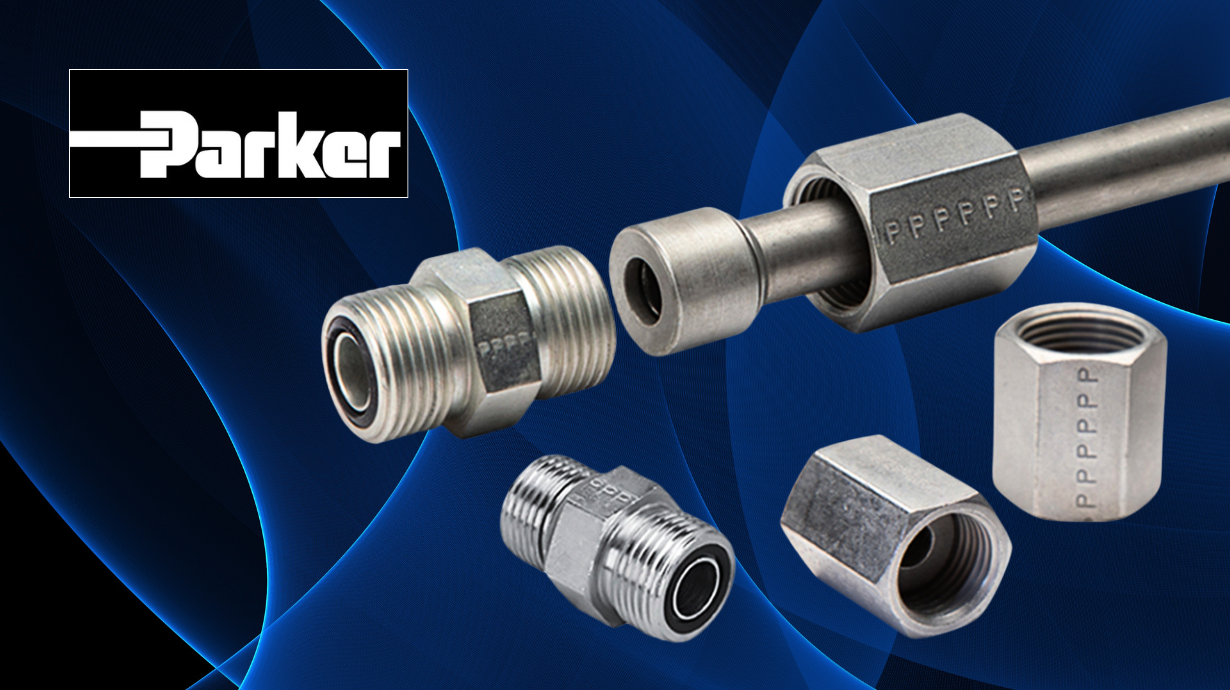

In any construction site or industrial plant, hydraulic system failures can be a major headache. When your tube assembly leaks or breaks, the clock starts ticking on costly downtime. For years, making high-pressure, leak-free O-ring Face Seal (ORFS) connections in the field meant dealing with slow, expensive, and cumbersome solutions. At Triad Technologies, we understand that time is money. That’s why we carry Parker Hannifin’s FastSeal technology, an innovative solution engineered to eliminate the most common jobsite headaches associated with hydraulic tube repairs and installations.

Posted: November 18, 2025Categories: Hydraulics -

Read more »

As a Premier Distributor of Parker Hannifin products, Triad is your go-to source for cutting-edge motion control solutions. Parker's D*F proportional valve family—specifically the D*FB, D*FC, and D*FP series—represents the pinnacle of hydraulic precision, offering unparalleled control for your most demanding applications. To help decide which is right for you, we’re breaking down the features, benefits, and ideal uses for each of these powerful proportional valves.

Posted: November 06, 2025Categories: Hydraulics -

Read more »

In the food, beverage, pharmaceutical, and biotech industries, sanitary process control isn’t just about precision - it’s about protecting product integrity and consumer safety. Every pressure and level reading impacts quality, consistency, and compliance. That’s why Triad is proud to carry NOSHOK sanitary pressure and level transmitters, engineered to deliver accurate, stable, and hygienic performance in the most demanding clean-in-place (CIP) and steam-in-place (SIP) environments.

Posted: October 30, 2025Categories: Hydraulics -

Read more »

Fall is a great time to perform routine maintenance checks on your hydraulic equipment before a broken part leaves you “out in the cold.” To ensure your hydraulic systems operate efficiently and reliably, check that your outdoor equipment is winterized and well-maintained. This is especially important for industries whose hydraulic systems experience regular exposure to the elements, such as construction workers, foresters, salt spreaders, snowplow operators, and more. Keep your business moving with these cold weather tips for operation of hydraulic equipment.

Posted: October 29, 2025 -

Read more »

As a leading distributor of Parker Hannifin cylinders, Triad knows that finding the perfect solution for your application can be challenging. Ensuring you get the best cylinder for the job protects your investment and prevents costly downtime caused by premature failure. For quick reference, we’ve compiled a list of key principles for cylinder selection, making it easy for our team to correctly select and size your next hydraulic or pneumatic cylinder.

Posted: October 15, 2025Categories: Hydraulics -

Read more »

A robust hose cover is a key factor in preserving the integrity of your hydraulic systems. It’s the first and often only line of defense protecting your hose in harsh operating environments. At Triad Technologies, we know that choosing the right hose cover can drastically extend the life of your hose assembly, reduce costly downtime, and enhance safety. That’s why we’re proud to carry Parker Hannifin ToughCover (TC), SuperTough (ST), Critical Protection (CP), and the related Tough Jacket (TJ) solutions!

Posted: October 09, 2025Categories: Hydraulics -

Read more »

Often referred to as "over-center" or "load-holding" valves, counterbalance valves from Parker Hannifin play a vital role in ensuring the safety, precision, and longevity of your hydraulic equipment. At their core, counterbalance valves are a pressure control device that creates back pressure on an actuator. This pressure helps with controlling a load's movement, especially when gravity is working against you.

Posted: September 18, 2025Categories: Hydraulics -

Read more »

Traditional hydraulic and electromechanical systems have long been the standard for linear motion, but they come with limitations. Hybrid Actuation Systems (HAS) from Parker Hannifin combine the power of hydraulics with the simplicity of an all-in-one electric actuator, making it easier than ever before to streamline your hydraulic control systems.

Posted: August 28, 2025Categories: Hydraulics