A Pocket Guide to Tube Line Clamping

STAUFF clamps are a staple in many industries, known for their reliable, secure hold on hydraulic hoses, tube, cables, and more. However, with a variety of types of clamps and product applications, navigating the world of STAUFF can feel overwhelming. This blog will answer some of the most frequently asked questions about STAUFF tube clamps and make it easier for you to find the perfect solution for your needs.

The Purpose of STAUFF Tube Clamps

Proper clamping is crucial for maintaining the efficiency, integrity, and longevity of hydraulic, pneumatic, and lubrication systems. The clamping of tube lines serves three purposes:

Vibration Dampening: In hydraulic and pneumatic systems, mechanical vibration is often the result of fluid flow, pressure fluctuations, and external factors such as machinery operation and environmental conditions. These vibrations, if left unchecked, lead to increased stress on network connections, fittings, and tubing material. Over time, this results in weak joints, leaks, and compromised system performance. Clamps help to prevent the transfer of vibration across tube lines, reducing the potential for failures and minimizing wear and tear to the system.

System Noise Reduction: Noise amplification is often the result of valve operation, cylinder actuation, and pump pulsations within the system. Properly placed tube clamps help minimize the transmission of system noise through the tube lines.

Tube Security & Longevity: Securing clamps to a rigid structure helps to effectively dissipate vibrations, preventing the system from transmitting vibrational energy, This helps to increase the service life of metal tube lines by preventing premature wear, fatigue, and potential failure of the tubing and associated components.

Choosing the Right STAUFF Clamp

Tube clamp systems come in many styles and materials. STAUFF offers a wide variety of plastic, aluminum, steel, and stainless steel clamping options, and those are just a few of the materials from which tube clamps can be manufactured. Multiple factors should be assessed to determine the proper tube clamp for your application, including material, application, temperature and environment. Some clamps may also be equipped with accessories, such as a rubber sleeves or elastomer inserts, which can be utilized to further dampen the vibration in the system. Triad Technologies' team of experts can help you choose the most suitable STAUFF clamp for your specific application. Shop our selection of STAUFF clamps online or contact us for personalized assistance.

Installation

Properly designed and installed tube clamps provide a stable anchoring point for the tubing, dampening vibration, preventing system noise, and protecting tubing from fatigue-related failures. Proper clamping also helps to maintain the structural integrity of the entire system. Here are a few installation tips:

1. Get the right clamp for the job. Consult with a Triad Technologies expert to determine the best solution for your application. It is important to note that clamps from different manufacturers may have different designs, centerline heights, and installation recommendations, so to ensure best results throughout the system it is recommended you install clamps from the same manufacturer, designed to work together efficiently.

2. Properly size clamps. Clamps are designed for tubes of a specific diameter. Clamps that are too large for your tube will not effectively prevent the tube from vibrating, while clamps that are too small may not secure properly and are likely to cause system damage. Matching tube with the appropriate clamp size ensures a secure hold and unrestricted fluid flow.

3. Secure clamps to a rigid structure. When clamping your tube line, it is important to secure the lines to a stable surface that can counteract vibrational forces. Without proper tube clamping, vibration can travel through a system and cause failures further down the line, resulting in unexpected downtime and increased maintenance costs.

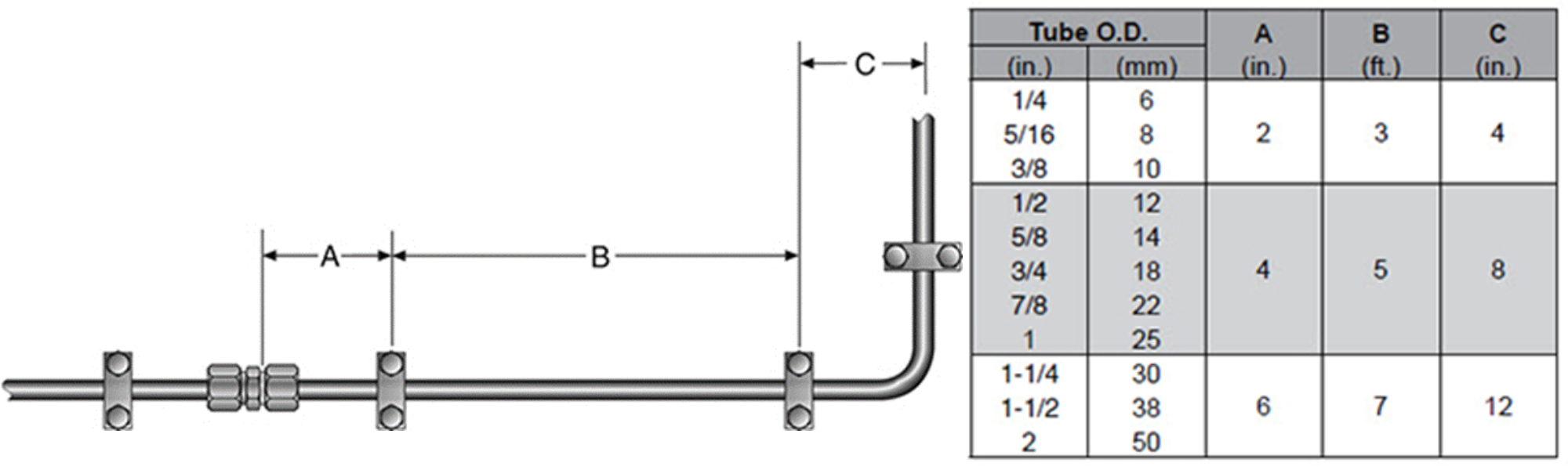

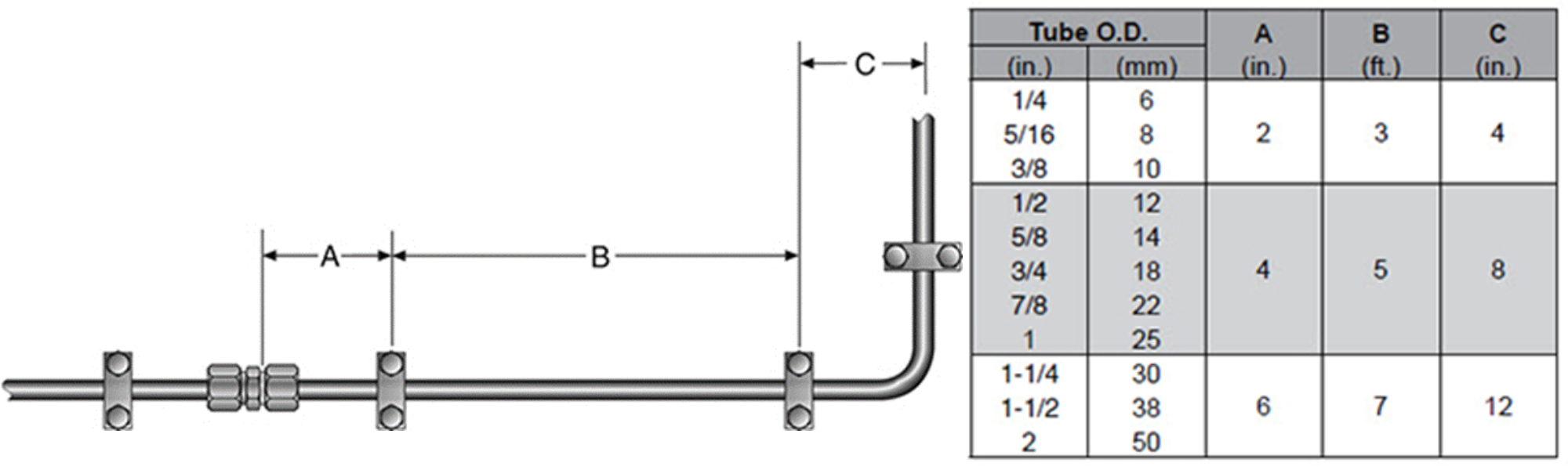

4. Properly space clamps along the tube line. A single clamp is often insufficient for preventing vibration in a system. The greater the distance between clamps, the greater the amplitude of vibration. See the chart below for recommended spacing of clamps.

5. For applications where multiple lines are being clamped, purchase clamps designed for multiple tube line clamping. Remember that these clamps must also be secured to a rigid surface to remain effective and properly dampen vibration, not just secured to the other tube lines.

Properly installed tube clamping systems contribute to overall system reliability, safety, and ease of maintenance, making them essential components in the design and installation of hydraulic, pneumatic, or lubrication systems.

Begin Your Clamping Installation

Triad Technologies is your authorized distributor for STAUFF clamps! Shop our extensive selection of STAUFF products directly through our online store, or contact our experts to discuss your next project or application. Our team is here to assist you every step of the way, from selecting the right clamp to providing expert advice and a convenient online store for your purchases.