Unlock Efficiency and Safety: Your Guide to Choosing the Right Loading Arm System

Choosing the right loading arm is crucial for seamless operations and employee safety. At Triad Technologies, we are proud distributors of advanced loading arm systems designed to optimize your material transfer processes. Many businesses handling liquids and gases at their terminals may not realize the significant advantages a well-chosen loading arm system can offer in terms of efficiency, safety, and operational costs. This guide will walk you through key considerations, helping you make an informed decision for your specific application.

While hoses offer a straightforward solution for some applications, loading arm systems are superior when it comes to:

Enhanced Safety: Loading arms reduce the need for manual handling, minimizing your team’s risk of slips, falls, and exposure to hazardous materials. Many systems even include features like dry disconnect fittings and emergency breakaway couplings that help to prevent spills.

Increased Efficiency: Loading arms offer faster and more consistent loading/unloading times, leading to higher throughput.

Improved Ergonomics: Designed for easier maneuverability, loading arms can often be operated by a single person.

Durability and Longevity: Built to withstand demanding industrial environments, loading arms may offer a longer lifespan compared to hoses.

Reduced Product Loss: Minimizes spills and fugitive emissions, safeguarding your facility and the environment.

To ensure you select the optimal loading arm system for your application needs, consider the following factors:

1. What type of products will I be handling and what are the material’s characteristics?

Viscosity: Liquids with different viscosities (for example, water and oil) require different arm configurations and flow rates.

Temperature: High or low temperatures may need specialized materials, insulation, or heating/cooling jackets to maintain product integrity.

Corrosivity/Hazardous Nature: Aggressive chemicals require compatible materials (e.g., stainless steel, aluminum, or specialized linings like PTFE) and appropriate seal materials.

Flammability/Volatility: Hazardous or volatile products require systems with advanced safety features, such as vapor recovery and sealed connections.

2. What is the physical layout of my space? Are there operational needs to consider?

Loading Method (Top vs. Bottom): Top loading is commonly used for railcars and truck tankers that have manholes on top. This method offers versatility and a wide range of options, suitable for various tank configurations. Bottom loading, on the other hand, is preferred for petroleum products due to standardization and enhanced safety, as the operator remains at ground level. It can also reduce overall loading time, especially for multi-compartment vehicles.

Number of Loading Positions: Plan for sufficient space for various arm configurations and loading points that will not interfere with nearby operations. Ensure arms have sufficient range to meet all of your planned loading points.

Obstructions: Account for existing structures like piping, light poles, support columns, meters, gangways, and safety cages when determining arm reach and movement. For covered bays, it is also important to consider roof height.

Structural Support: Loading arms can be heavy! Ensure your facility has adequate structural support for safe and smooth operation.

Flow Rate Requirements: Your desired throughput will determine the necessary pipe size and overall system design.

3. Are there specific configurations or customized features to consider when designing my loading arm?

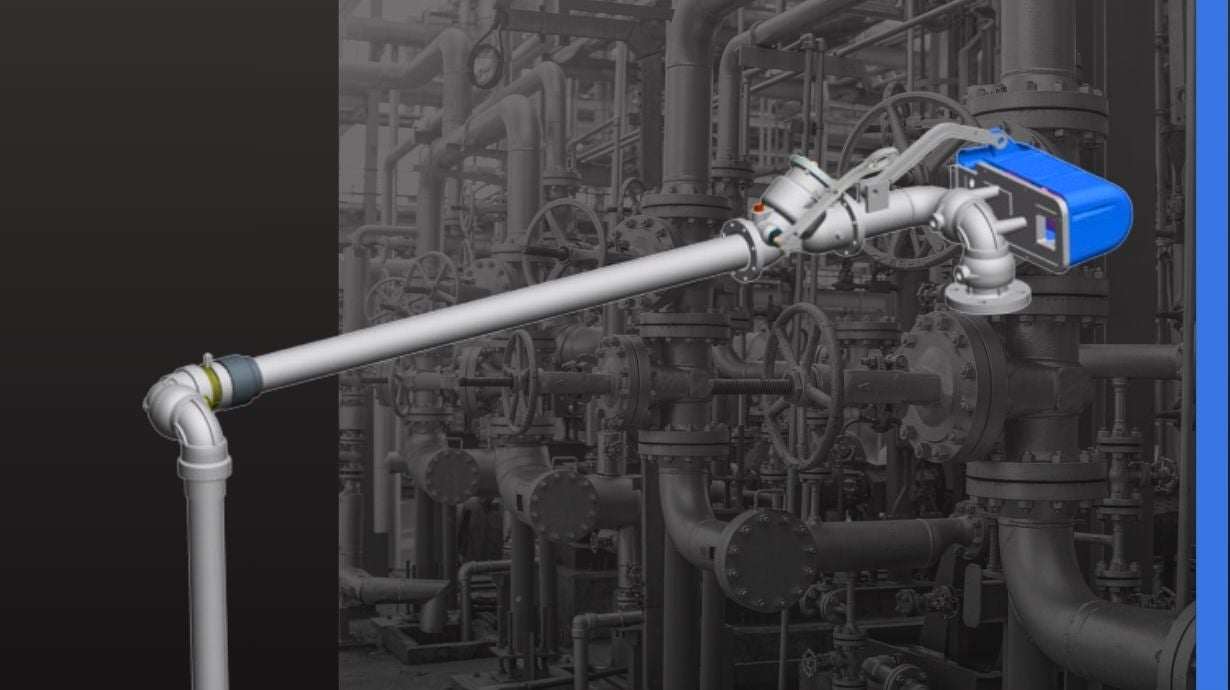

Configurations: Common types include A-frame, horizontal, scissor-style, and supported or unsupported boom arms.

Materials: Common materials include carbon steel, stainless steel, and aluminum, chosen based on chemical compatibility and strength.

Swivel Joints: These components allow for multi-directional movement, but it is critical that they are robust, appropriate for your application, and compatible with materials.

Balance Mechanisms: Counterweights or spring balance cylinders can ensure smooth and safe vertical movement and easy positioning.

Safety Features: Dry-break couplers, emergency release systems, overfill prevention, and level detection systems can enhance system safety and prevent spills. Other features, such as welding or insulation, may be valuable tools for personnel safety.

Accessories: Consider quick-connect couplers, vapor recovery fittings, and manual or actuated valves to optimize operations.

4. How does my loading arm system integrate with my existing infrastructure?

Existing Equipment: Ensure loading arms are compatible with your current piping, metering systems, gangways, loading platforms, and fall prevention cages.

Vehicle Compatibility: Confirm that the chosen loading arm is compatible with your specific truck and/or railcar designs.

At Triad Technologies, we understand that selecting the right loading arm is a significant investment. Our experienced team can provide expert guidance, evaluating your unique operational needs, product characteristics, and site limitations to recommend the ideal loading arm system for your application. We are committed to helping you achieve maximum efficiency, safety, and reliability in your fluid transfer operations. Contact us today to learn more about our loading arm solutions and how we can help you optimize your terminal operations.