Don’t Get Your Signals Crossed: How Encoders Support Manufacturing

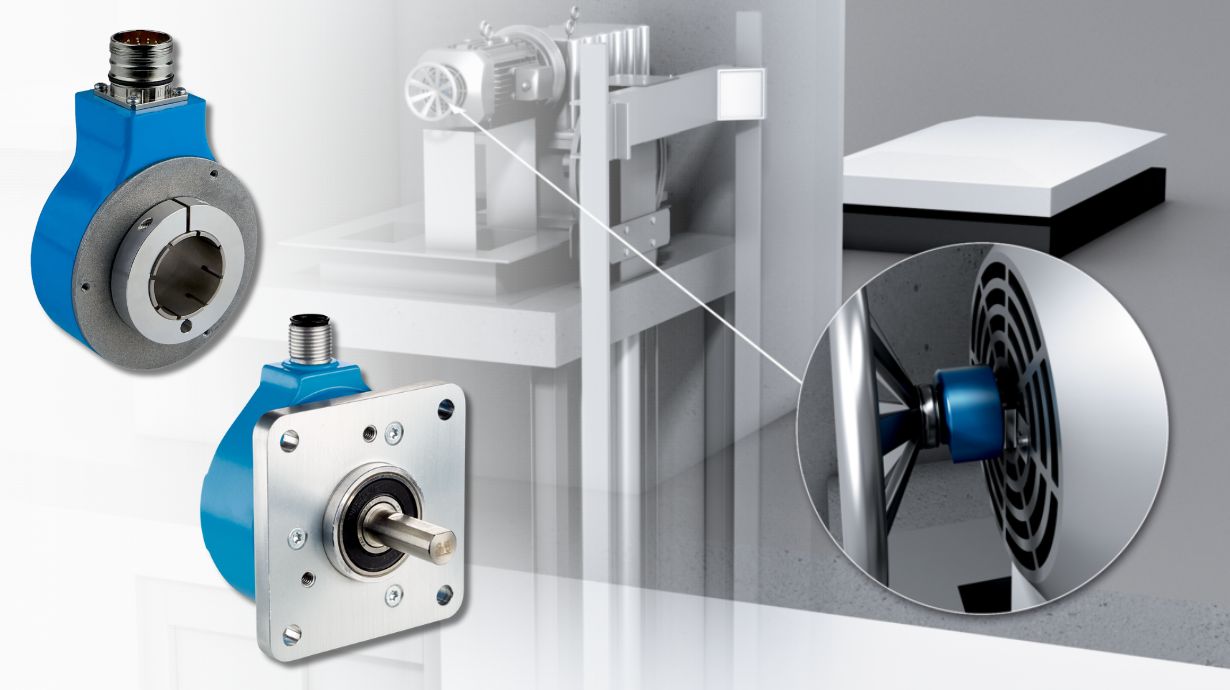

In the world of manufacturing, precision is paramount. Every tiny movement of a machine needs to be carefully controlled and monitored to ensure consistent, high-quality performance and production. This is where encoders come in! Encoders are essentially sensors that convert physical motion into digital pulses or electrical signals. These signals can then be read by a control device, which is used to determine an object’s position, angle, and rotation counts – data that is crucial for machines moving exactly as they should.

Though you may not realize it, encoders are used in a wide variety of manufacturing applications, including:

Assembly lines: Encoders can be used to track the position of parts as they move down an assembly line, ensuring that they are placed in the correct locations.

Robotics: Encoders are essential for controlling the movement of robotic arms, allowing them to perform tasks with high precision.

Conveyor belts: Encoders can be used to monitor the speed of conveyor belts, ensuring that products are transported at the correct speed.

Printing presses: Encoders can be used to control the position of the printing head, ensuring that images and text are printed in the correct locations.

Most encoders fall into two main categories: absolute and incremental.

Absolute encoders provide a unique signal for every position within their range of motion. This eliminates the need for homing procedures after power interruptions, allowing for immediate operation. These encoders are ideal for applications where precise positioning is critical, or for applications that require immediate position feedback after power cycles or unexpected stops.

Incremental encoders, on the other hand, produce a pulsed signal as their position changes. This allows them to provide fast, precise, and high-resolution feedback on motion. While less expensive than their absolute counterparts, these encoders require a brief homing procedure after power loss to determine position, making them unsuitable for applications demanding an immediate restart.

Choosing the right encoder depends heavily on your specific application requirements. If immediate position feedback is crucial after power interruptions or unexpected stops, absolute encoders are the preferred choice. However, applications demanding high resolution and precise position feedback, such as those involving high-speed motion, may benefit from the cost-effectiveness and high resolution of incremental encoders.

In short, encoders may be small, but they play a huge role in making modern manufacturing possible. As your local automation distributor, Triad Technologies offers several encoder solutions from brands you trust, such as SICK, Encoder Products Company, TR Electronic, Baumer, and more! Contact Triad Technologies today to discuss your automation needs and determine which encoder is right for you. You can also schedule a visit to our automation lab to test encoders firsthand and qualify them for your application. Don’t get your signals crossed when it comes to precision – achieve high-quality performance and positioning with reliable encoders from Triad!