Stop Hydraulic Leaks & Downtime: How Parker FastSeal Revolutionizes ORFS Tube Connections

In any construction site or industrial plant, hydraulic system failures can be a major headache. When your tube assembly leaks or breaks, the clock starts ticking on costly downtime. For years, making high-pressure, leak-free O-ring Face Seal (ORFS) connections in the field meant dealing with slow, expensive, and cumbersome solutions. At Triad Technologies, we understand that time is money. That’s why we carry Parker Hannifin’s FastSeal technology, an innovative solution engineered to eliminate the most common jobsite headaches associated with hydraulic tube repairs and installations.

Traditional methods for hydraulic tube assembly are often associated with wasted time, soaring costs, and quality issues. Here are the three most common problems FastSeal is designed to solve:

Excessive Downtime: When a hydraulic line fails, getting your equipment back online quickly is the priority. However, older methods like brazing and flanging often require expert technicians, specialized machinery not readily available onsite, and extensive time for repairs or curing. The result is lost hours, missed deadlines, and equipment sitting idle while waiting for tools or skilled personnel.

Special Equipment & Logistical Nightmares: Brazing requires precise temperature control and cooling time, making it impractical in tight or remote field conditions, while flanging requires bulky, dedicated flanging equipment that can be expensive and difficult to use in confined spaces. In both cases, specialized tooling and equipment mean higher capital expenditures, increased maintenance costs, and higher logistical costs for moving equipment between jobsites. For many companies, this equipment sits idle most of the time, making the total cost of ownership disproportionately high for occasional repairs.

Connection Errors & Installation Damage: Even with the right equipment, the potential for human error is high. Traditional fittings require multiple steps and precision to ensure a perfect seal. An improperly brazed or poorly flanged connection can easily lead to leaks, which can be instantaneous or develop under high impulse pressure if the tube surface is damaged or the seal isn't properly seated. Re-working seals can fix the problem, but it also adds substantial time and material waste.

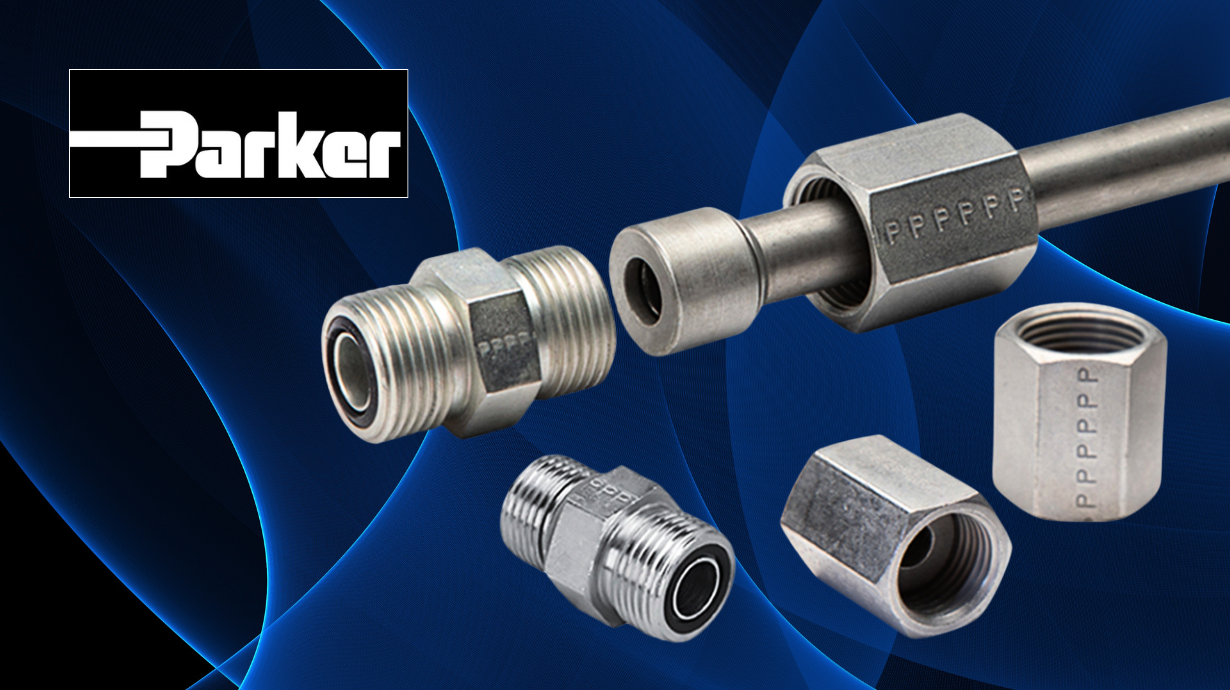

Parker’s patent-pending FastSeal technology transforms the way you approach hydraulic tube assemblies. It combines the proven strength of a bite-type fitting with the superior sealing capability of an ORFS (O-Ring Face Seal) fitting into a single, revolutionary nut. The core difference is simplicity: all you need is a wrench.

|

Jobsite Problem Solved |

FastSeal Advantage |

Result |

|

Excessive Downtime |

Field-Ready Assembly: Eliminates the need for brazing or flanging. |

Systems get back online in minutes, not hours. |

|

High Installation Costs |

Wrench-Only Tooling: No specialized or expensive machinery required. |

Reduced capital investment and lower logistical costs. |

|

Leaky Connections |

Integrated Seal Dynamics: Combines a bite ring for mechanical grip and an O-ring for a leak-free seal. |

Reliable, robust connections that meet or exceed SAE and ISO standards. |

|

Tube Repair Complexity |

Splice Capability: Can be used with a standard union to quickly splice and repair a damaged section of tube. |

Quick, effective on-site repairs for pinhole leaks and minor damage. |

FastSeal simplifies the assembly process to just three steps: Mark, Insert, and Tighten the tube. The bite-ring presets cleanly onto the tube end, guaranteeing a permanent, secure flat-face connection that works seamlessly with Parker Seal-Lok ORFS fittings.

Stop losing time and money to obsolete installation methods. By choosing FastSeal, you’re investing in reliability, efficiency, and a drastic reduction in your overall operating costs. FastSeal is available to order online or in Triad’s Maumee, Vandalia, Elkhart, Brecksville, and McCook ParkerStore locations. To learn more about integrating this leak-free hydraulic connection technology into your next project or maintenance routine, contact the experts at Triad Technologies today!