Key Factors to Consider When Choosing the Right Seal for Your Application

Selecting the right seal isn’t just about matching dimensions. It’s about ensuring system reliability, maximizing uptime, and protecting equipment performance. The wrong seal can lead to leaks, contamination, unplanned downtime, and costly repairs.

Here are the key factors to consider when selecting a seal for your application:

1. Material Compatibility

Seal material must be compatible with the fluid or gas in your system. In hydraulic applications, oil-resistant compounds such as NBR, FKM, and polyurethane are commonly used. For pneumatic systems, internally lubricated polymers help reduce friction and wear during dry running.

Why it matters:

An incompatible material can swell, harden, crack, or chemically degrade — leading to premature failure and leakage.

2. Pressure Ratings

Hydraulic systems often operate at thousands of psi, while pneumatic systems stay under 150 psi. Seals must be designed to resist extrusion, deformation, and wear under these operating conditions.

Tip:

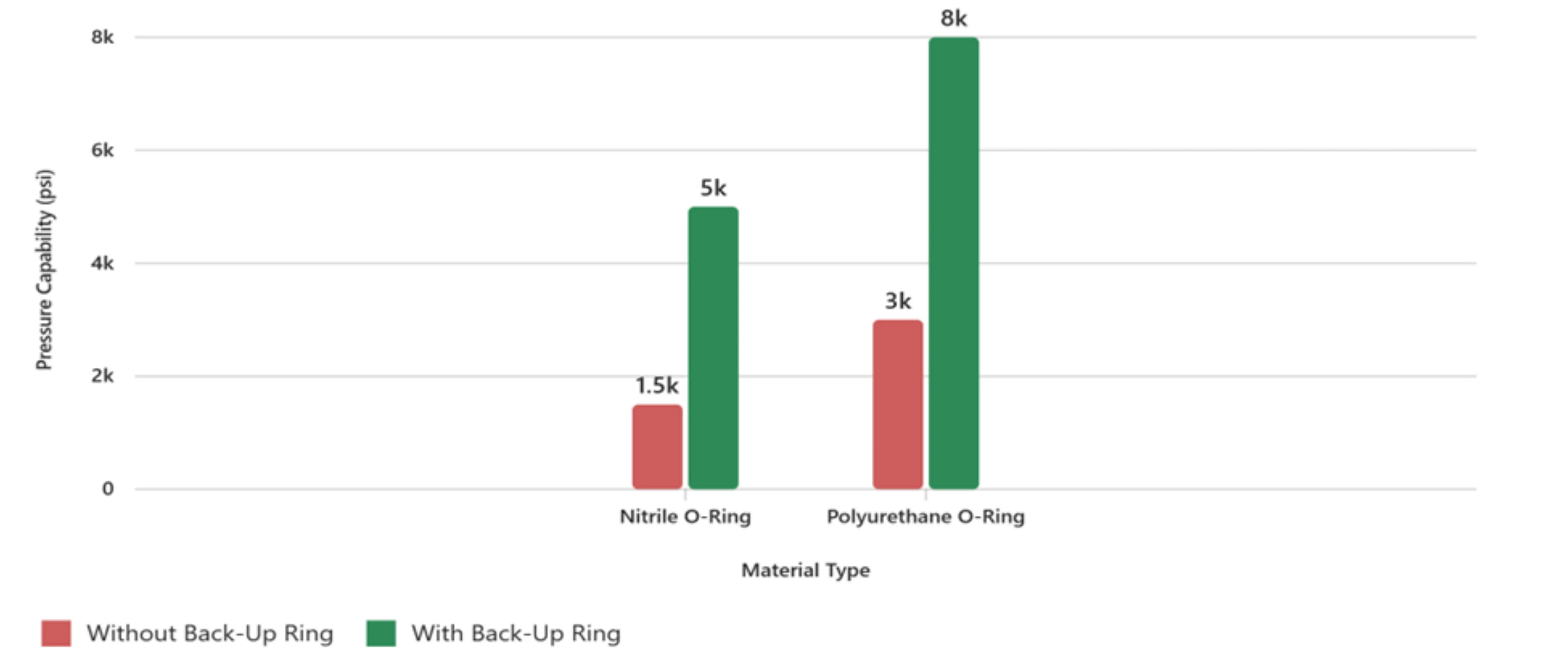

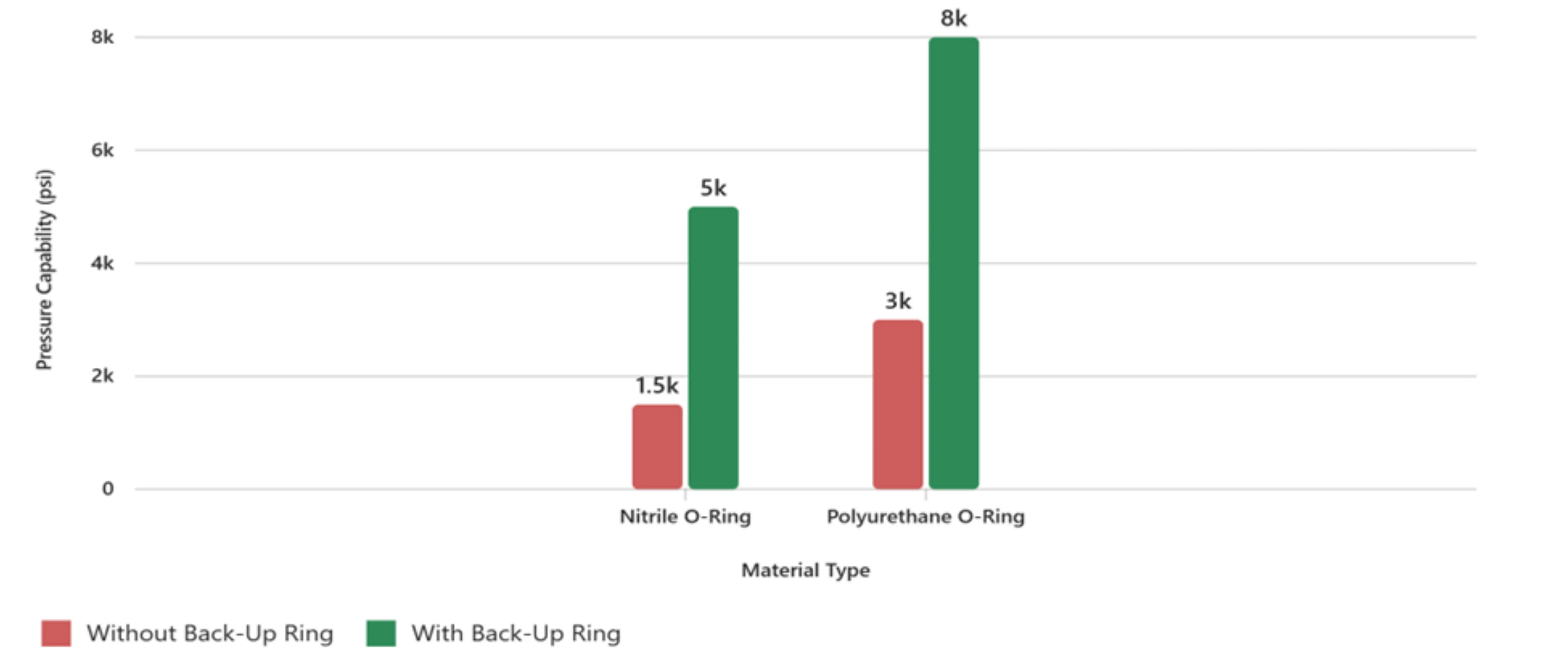

For high-pressure applications, consider seals with anti-extrusion features or pair them with back-up rings for added support.

3. Environmental Conditions

Environmental factors play a major role in seal performance and longevity.

High heat: Fluorocarbon elastomers (such as FKM) provide excellent heat resistance.

Dusty environments: Wiper seals help keep contaminants out and protect internal components from damage.

Food & medical applications: FDA-compliant materials are essential for safety and regulatory compliance.

Low temperatures: Specialized rubber blends or low-temperature polyurethane maintain flexibility and sealing integrity.

Ignoring environmental conditions can shorten seal life and increase maintenance frequency.

4. Dynamic vs. Static Applications

Dynamic seals (such as rod and piston seals) require low-friction materials and optimized profiles to minimize wear. High speeds and rapid pressure reversals require special consideration.

Static seals (such as O-rings) focus on compression and chemical resistance.

Selecting the wrong profile for the application can lead to excessive wear or leakage.

The Role of Back-Up Rings

Back-up rings prevent extrusion in high-pressure systems by supporting the primary seal. This simple addition can dramatically extend seal life, improve reliability, and help prevent catastrophic failure.

Final Thoughts

Choosing the right seal requires balancing material compatibility, pressure, environmental conditions, and application design. Overlooking even one factor can lead to premature failure, downtime, and increased maintenance costs.

If you’re unsure which seal is right for your system, our team can help evaluate your application and recommend a reliable solution. Contact us today to get started.