Mumbo Jumbo to Masterclass: Decoding Laylines Like a Pro

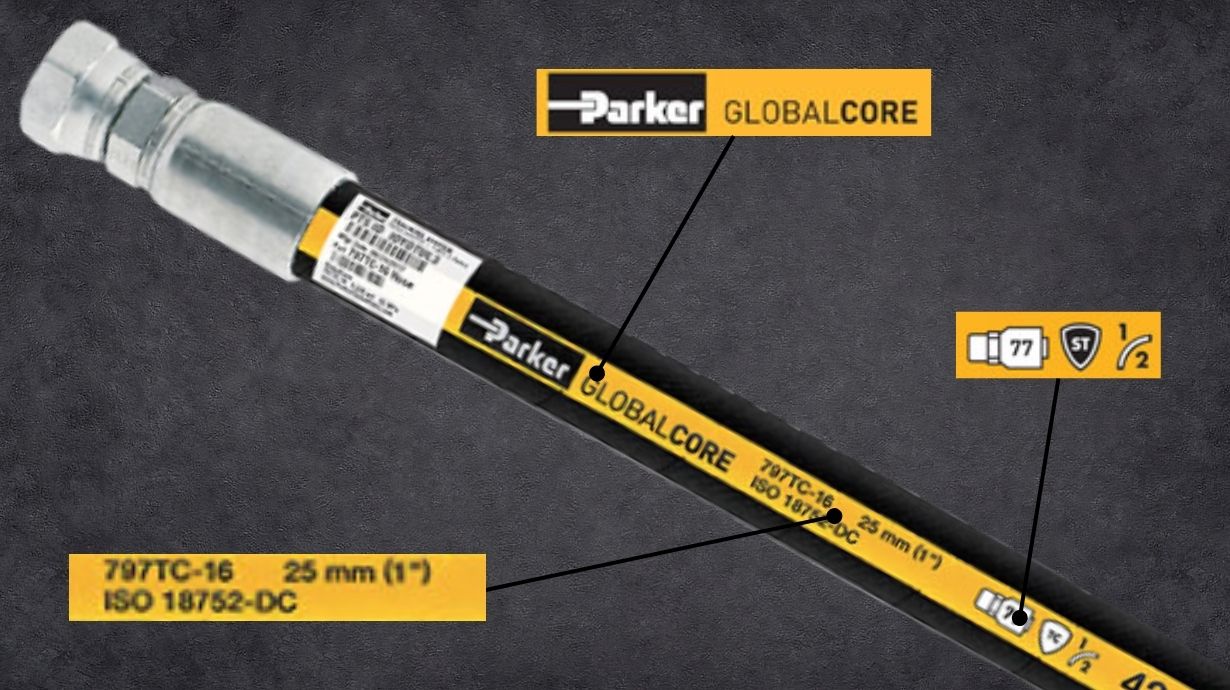

Ensuring you have the right hydraulic hose for the job is crucial, especially when there are so many options to choose from. Parker Hannifin makes hose identification easy by printing vital information directly onto hoses in the form of laylines. These markings hold a wealth of information about a hose's capabilities and specifications, empowering you to make informed decisions about your hydraulic system.

Decoding a layline starts with recognizing the key elements. A Parker Hannifin layline typically consists of the following:

Manufacturer Logo: The first thing to notice is the Parker logo. This identifies Parker as the manufacturer and indicates the starting point for information printed on the layline.

Hose Family/Designation: This indicates which series the hose belongs to. In this case, the hose is part of Parker’s GlobalCore Hose Family.

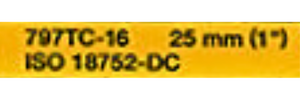

Part Number: This unique identifier specifies the exact hose type and configuration. In this case, the product number is 797TC.

Dash Size/Hose Diameter: Represents the nominal inside diameter of the hose in sixteenths of an inch. For example, here, "-16" signifies a 1” inner diameter.

Industry Standards: Indicates industry standard compliance. This hose complies with ISO 18752-DC.

Fitting Icon: This icon shows the size of fitting the hose is compatible with. The hose pictured is compatible with series 77 fittings.

Cover Type/Abrasion Resistance: This icon indicates the hose's ability to withstand external wear and tear. “ST” is an abbreviation for Parker’s SuperTough Cover.

Minimum Bend Radius: Defines the tightest curve the hose can safely bend without compromising its integrity. The minimum bend radius for our example hose is ½.

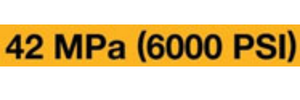

Working Pressure: Indicates the maximum continuous pressure the hose can safely handle in both mega pascals (42 MPa, in this case), and pounds per square inch (6000 PSI).

Temperature Range: Specifies the operational temperature limits for the hose. Our example hose’s working temperature range is -40C to 125C, or -40F to 257F.

Manufacturing Data: This section reveals manufacturing data to help with hose traceability and quality control. Data includes a plant code, manufacturing location, and manufacturing date code.

Some laylines may feature additional data, such as approvals for specific industries or a “No-Skive” indicator for assembly. Our ParkerStore associates can help you identify and decode these additional icons and codes if they appear on your hose. The layline can also be used as a visual indicator during hose installation to verify that a hose is not twisted or kinked.

Now that you know how to interpret layline details, you are equipped to choose hoses perfectly matched to your specific application, ensuring optimal performance and system longevity. Find your next hose by visiting your nearest Triad Technologies ParkerStore or contacting us online today!