Parker's Twinhammer™ Hose Supports Safer & Healthier Construction Jobsites

About 2.3 million workers are exposed to respirable crystalline silica (RCS) in their workplaces, according to OSHA. This includes 2 million construction workers who drill, cut, crush, or grind silica-containing materials such as concrete and stone.

RCS can embed in the lungs of unprotected workers, causing serious, even debilitating health issues or death from conditions such as lung cancer, chronic obstructive pulmonary disease (COPD), kidney disease or silicosis.

To protect workers, OSHA has now created a new standard to help employers address this problem of crystalline silica dust control associated with operation of jackhammers, breakers, drills, saws, grinders and other tools in the construction industry. The OSHA standard considers a "wet method" of dust suppression an effective tactic in a properly deployed strategy. The wet method suppresses dust by spraying a constant and appropriate volume of water directly onto the tip of the jackhammer where it meets the work object. The water grounds the dust before it becomes an airborne health hazard.

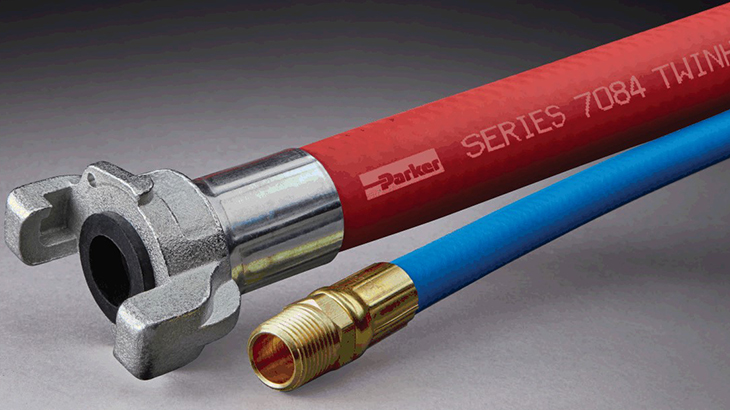

Parker's Twinhammer™ Dual Air/Water Jackhammer Factory Hose Assemblies is an integral component of a dust suppression system, as the new twin line hose system transfers air to power heavy duty pneumatic jackhammers/breakers while simultaneously transferring water to suppress silica dust produced by tool operation. You can pick up a Twinhammer hose at any of our ParkerStores.

Learn more about the Respirable Crystalline Silicia Standard:

(Infographic created by Parker Hannifin)