Solutions for Success: Unitronics & The Ohio Glass Museum

Customer/Background

The Ohio Glass Museum in Lancaster, Ohio provides both a visual and hands-on learning experience for visitors. The hands-on experience is through regularly scheduled classes that utilize a Stadleman Glassworks electric furnace that can hold a 300# charge.

Challenge

The preparation for a class requires charging the furnace and executing a specific charge/cook heat cycle in order to properly melt and prepare the glass for use. The charge cycle alone can require many hours and the cook cycle requires 8 hours. The installed temperature controller, while very functional, was limited to its single capability of holding the temperature that it was set to. Since times and cycle time/temperature changes could not be programmed, this meant that the furnace had to be monitored and manually changed from cycle to cycle. Quite often this was not during the typical workday, usually occurring during the night and/or early morning.

Solution

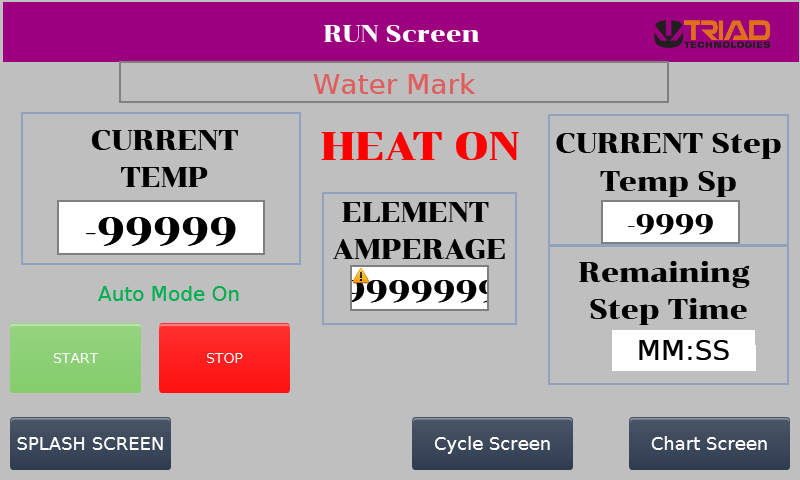

New Controller - Main Screen

New Controller - Main Screen

The setpoint controller was replaced with a Unitronics 5” built in unit. This unit has both digital I/O and temperature inputs included. Simple programing was implemented to provide specific pre-programed cycles for heat, cool-down, charge and cook. The program now also has the ability to automatically switch between

cycles based on time and temperature setpoints.

As additional benefits, the system can now set alarms that are specific to the current active cycle and also monitor the current to the heating elements to help identify heating element problems before they become major repairs. The current monitoring is provided by a Socomec DIRIS power monitor.

Implementation

A single day was required to install the new controller and get the furnace running on the new program.

Results

The Unitronics solution provides the needed functional benefits as well as providing a graphic representation of the status, including logging and graphing, to help describe status and functional operation.

Let's talk about how our automation products can help improve your processes and applications. Contact us today!