Extend the Service Life of Your Hydraulic Hose with Proper Routing

Proper hose routing is essential in maintaining the integrity of your hydraulic hose and preventing future damage that can lead to failure. A well-routed hose is properly fitted and installed, and has the appropriate space for regular maintenance and service. Here are some quick tips to keep your hydraulic hose in peak condition:

Plan Hose Layouts Prior to Installation: When designing hydraulic systems, you are often limited by your machine’s configuration and components. By planning the layout of system components in advance, you can avoid crossed lines, pinch points, and unnecessary damage, as well as prepare for challenges such as tight spaces or bends. When possible, it is best practice to run hydraulic lines parallel to your equipment, making sure to route the hose through pivot points as needed and install clamps to avoid excessive hose movement. Make sure that hoses are easy to access for service and repair, whenever possible.

Consult the STAMP Method: Once your layout has been plotted, it is time to purchase the appropriate hose. When a hose is used in an application it was not designed for, the life of that hose is significantly decreased, and failure or serious injury may occur. To reduce the chance of failure from misapplication, it is important to know the size, temperature, application, media, and pressure (STAMP) required by your system. Hoses that are too long will cost more in material and are more susceptible to damage from contact with external factors, while hoses that are too short or the wrong material may experience premature failure due to strain. Consult Section E of Parker Hannifin's Hose Products Division Catalog to determine the hose you need “STAMP” of your equipment, then visit your Triad Technologies ParkerStore and let one of our experts create a hose to meet your exact specifications in just a few minutes!

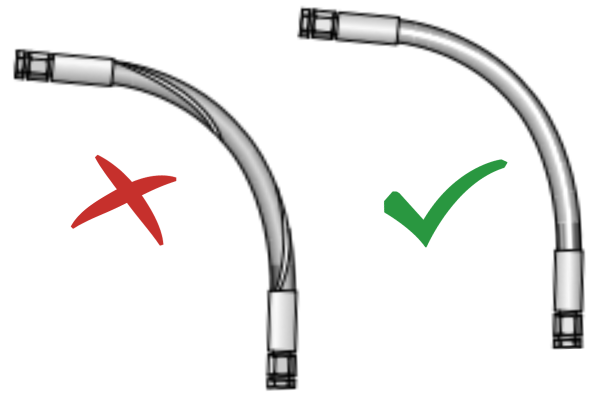

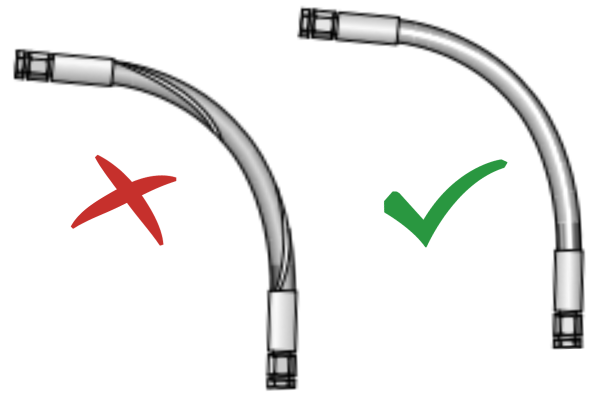

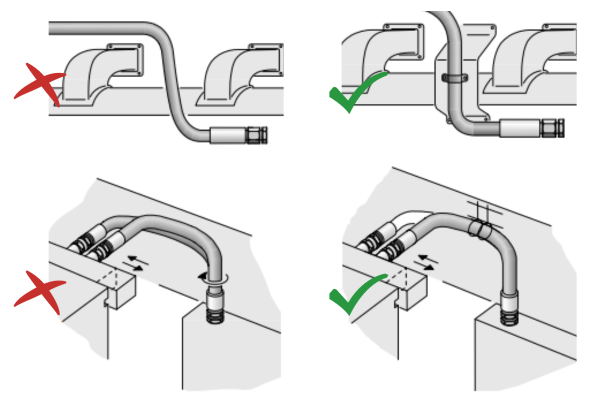

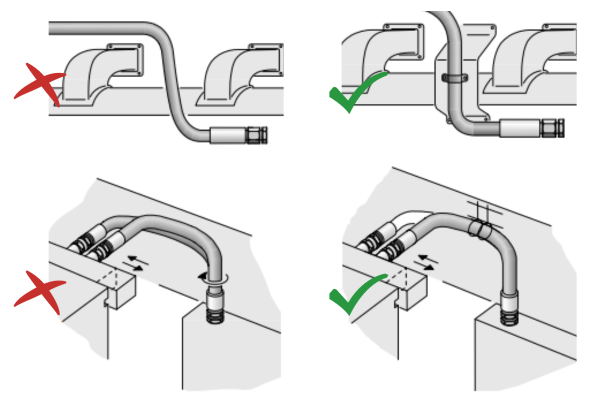

Avoid Twisting Hose During Installation: Hoses should always be installed with the lay line bending only with a single curve of the hose, not twisting around it. A twisted hose will result in a reduced service life. If a hose needs to bend on more than one plane, break up the hose into multiple sections to prevent twisting.

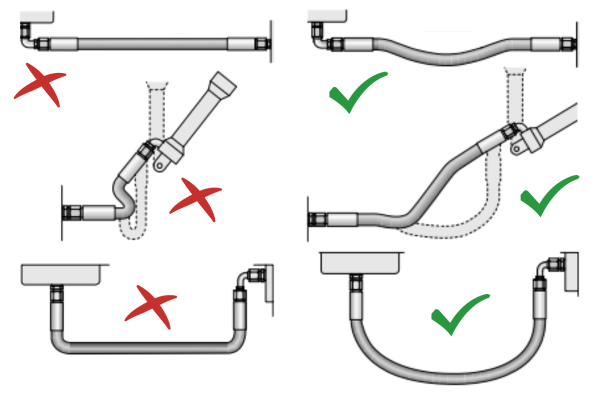

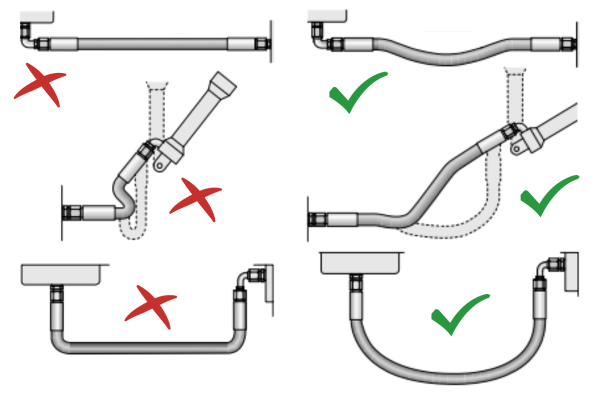

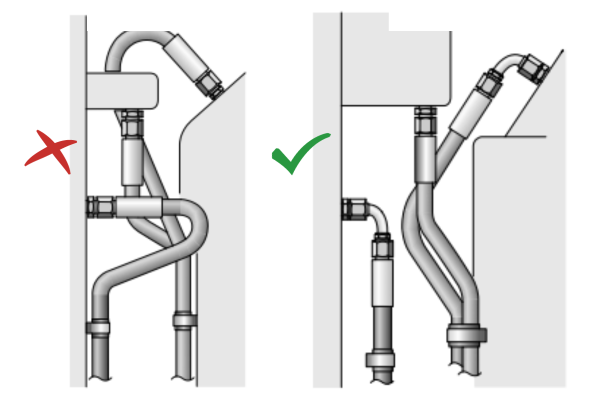

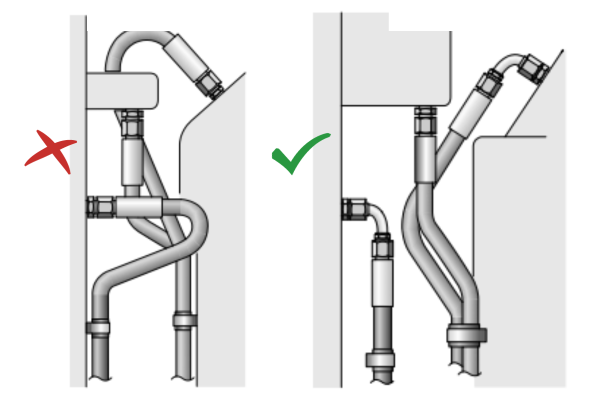

Leave the Appropriate Amount of Slack: When a hose assembly becomes pressurized, its diameter is stretched and its length shrinks slightly. When hoses are fully extended at installation, this stretch may cause the hose to become too short at pressurization, leading to decreased service life and possibly failure. To prevent this, leave a slight bend in hose routes so that hoses can move and stretch without creating tension. However, be sure not to leave so much slack in the system that hoses are able to rub against other components.

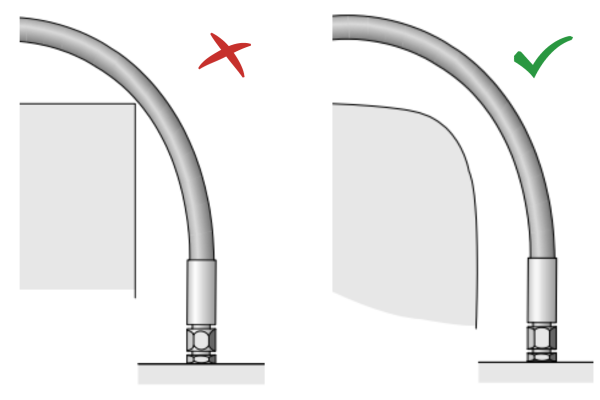

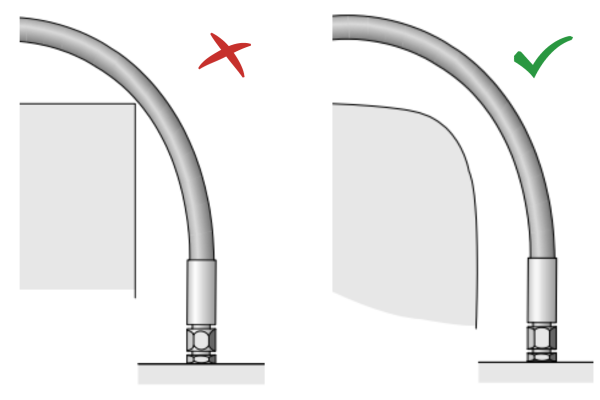

Allow for Adequate Bend Radius: Make sure your hoses are long enough to reach both end ports without creating kinks. Never bend the hose tighter than the minimum bend radius specified by the hose’s manufacturer, as this can lead to increased pressure and ruptured joints. If the space available for your hose causes it to exceed the minimum bend radius, or creates a kink near your fitting, use elbows or other adapters to redirect the hose and ensure its integrity.

Prevent Excessive Movement: Use clamps to secure your hose and prevent it from getting caught in surrounding parts. An appropriately sized clamp should grip your hose firmly without compressing it. Clamps should accommodate 2% increase in diameter and 4% decrease in hose length for best results. Choosing a more restrictive clamp than this can prevent the hose from changing lengths under pressure, causing damage to both the clamp and hose. Additionally, be sure to avoid clamping high and low-pressure hoses together, as the different changes in length may cause the hoses to rub against one another.

Protect from Damaging External Factors: When installing hoses, check for exposed edges and abrasive surfaces that can cause damage to the outer layer of hose. Use clamps to redirect hoses away from these surfaces, or consider using an abrasion-resistant cover to protect hoses from punctures and cracking.

No matter what the application, Triad Technologies has hydraulic hoses, fittings, accessories, and tips to keep your business moving! Contact us with questions about routing best practices, or visit your local ParkerStore to begin your project today!